Supplementary information: Test methods used during development or manufacture: Measurement of consistency by penetrometry

This text is reproduced from the European Pharmacopoeia with permission and with appropriate editorial modifications.

This test is intended to measure under determined and validated conditions the penetration of an object into the product to be examined in a container with a specified shape and size.

Apparatus

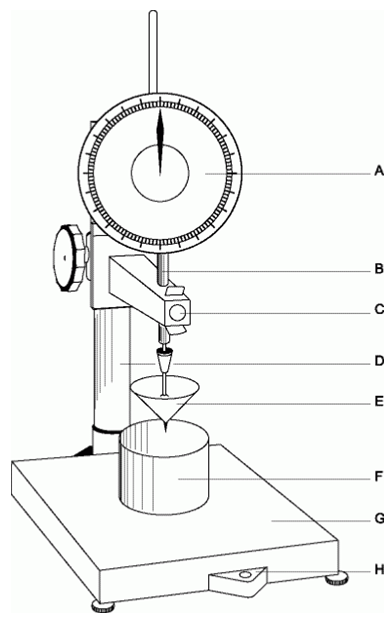

The apparatus consists of a penetrometer made up of a stand and a penetrating object. A suitable apparatus is shown in Figure 1.

The stand is made up of:

- a vertical shaft to maintain and guide the penetrating object;

- a horizontal base;

- a device to ensure that the penetrating object is vertical;

- a device to check that the base is horizontal;

- a device to retain and release the penetrating object;

- a scale or suitable digital analyser showing the depth of penetration, graduated in tenths of a

- millimetre.

The penetrating object, made of a suitable material, has a smooth surface and is characterized by its shape, size and mass (m).

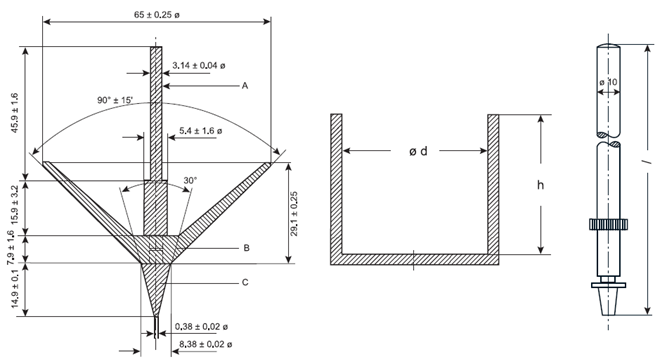

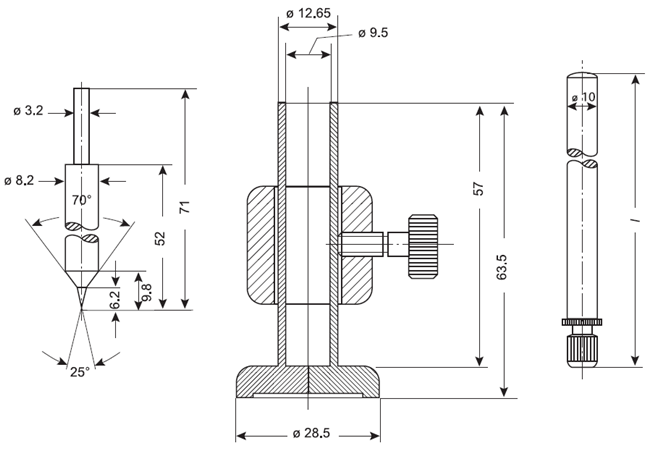

Suitable penetrating objects are shown in Figures 2 and 3.

Procedure

Prepare the test samples according to one of the following procedures.

A. Carefully and completely fill 3 containers without forming air bubbles. Level if necessary to obtain a flat surface. Store the samples at 25 ± 0.5 °C for 24 h, unless otherwise prescribed.

B. Store 3 samples at 25 ± 0.5 °C for 24 h, unless otherwise prescribed. Apply a suitable shear to the samples for 5 minutes. Carefully and completely fill 3 containers without forming air bubbles and level if necessary to obtain a flat surface.

C. Melt 3 samples carefully and completely fill 3 containers without forming air bubbles. Store the samples at 25 ± 0.5 °C for 24 h, unless otherwise prescribed.

Figure 1. Penetrometer

A. Scale or suitable digital analyzer showing the depth of penetration, graduated in tenths of millimetres.

B. Vertical shaft to maintain and guide the penetrating object.

C. Device to retain and to release the penetrating object automatically and for a constant time.

D. Device to ensure that the penetrating object is vertical and that the base is horizontal.

E. Penetrating object (see Figures 2 and 3).

F. Container.

G. Horizontal base.

H. Control for the horizontal base.

Figure 2.

Cone (m = 102.5 ± 0.05 g), suitable container (d = 102 mm or 75 mm; h ≥ 62 mm) and shaft (l = 162 mm; m = 47.5 ± 0.05 g)

Dimensions in millimetres.

Figure 3.

Micro-cone (m = 7.0 g), suitable container and shaft (l = 116 mm; m = 16.8 g)

Dimensions in millimeters.

Determination of penetration

Place the test sample on the base of the penetrometer. Verify that its surface is perpendicular to the vertical axis of the penetrating object. Bring the temperature of the penetrating object to 25 ± 0.5 °C and then adjust its position such that its tip just touches the surface of the sample. Release the penetrating object and hold it free for 5 seconds. Clamp the penetrating object and measure the depth of penetration. Repeat the test with the 2 remaining containers.

Expression of results

The penetration is expressed in tenths of a millimetre as the arithmetic mean of the 3 measurements. If any of the individual results differ from the mean by more than 3% repeat the test and express the results of the 6 measurements as the mean and the relative standard deviation.